Artistry in aluminum casting is a magnificent fusion of science and creativity, where molten metal is transformed into intricate and durable forms. A356 Aluminum Casting has evolved over centuries, from its humble beginnings as a means to create simple tools and artifacts to today’s sophisticated process of crafting beautiful and robust pieces of art. In this blog, we’ll delve into the world of aluminum casting, exploring its history, techniques, and the remarkable fusion of beauty and strength that defines this craft.

The Historical Evolution

Aluminum is one of the most abundant elements on Earth, but it wasn’t until the 19th century that it was successfully extracted and used in casting. Early aluminum casting methods were rudimentary, resulting in rough and irregular shapes. However, the discovery of more advanced casting techniques, such as sand casting and die casting, transformed aluminum into a versatile material for artistry.

- Sand Casting: Sand casting is one of the oldest and most traditional methods of aluminum casting. It involves creating a mold from compacted sand and then pouring molten aluminum into it. This technique allows for intricate designs and is often used in sculptural artistry.

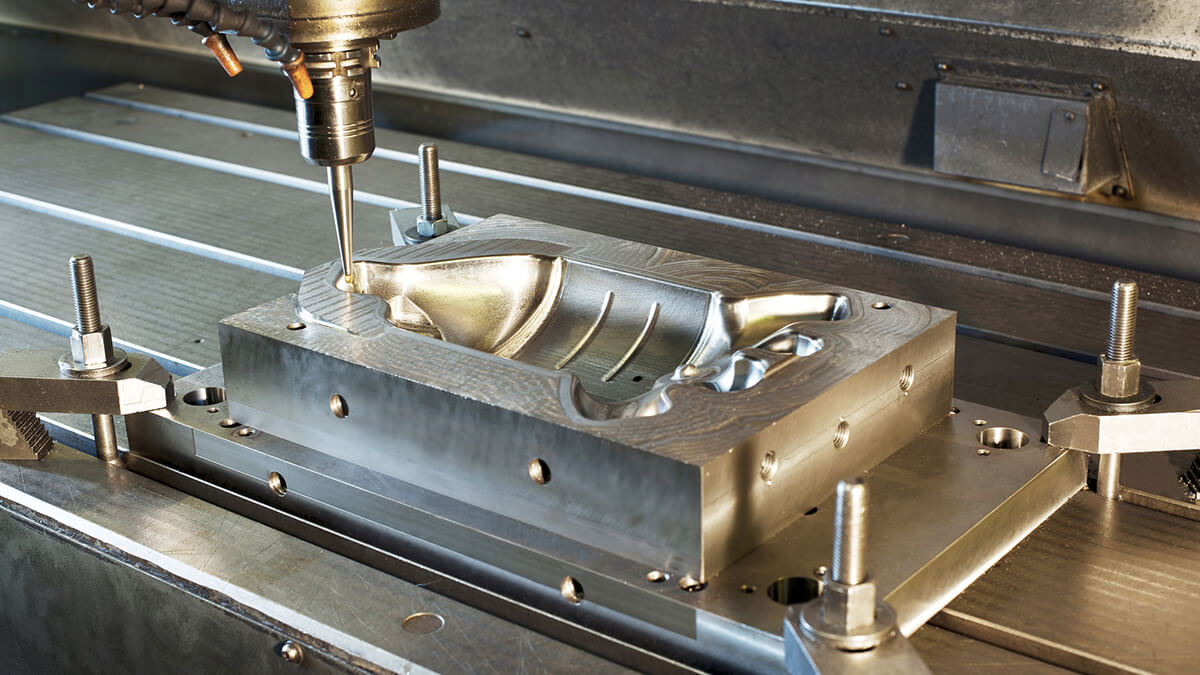

- Die Casting: Die casting is a more precise method used for mass production of aluminum parts. A metal mold, or die, is used to shape the molten aluminum, resulting in consistently accurate and detailed pieces.

Crafting Beauty

Aluminum casting, when approached as an art form, is a medium for expressing creativity and beauty. Artists and craftsmen have harnessed the properties of aluminum to create breathtaking sculptures, intricate jewelry, and functional art pieces. Here’s how beauty is crafted through aluminum casting:

- Intricate Detail: Aluminum’s malleability allows artists to create intricate details and textures in their designs, from the delicate curves of a figurine to the fine etchings on a jewelry piece.

- Versatile Finishes: Aluminum can be polished to a high sheen, anodized for vibrant colors, or given a patina for an aged appearance. These finishes add depth and character to the final product.

- Sculptural Possibilities: Sculptors have embraced aluminum casting for its ability to capture the essence of form and movement. Whether it’s a lifelike figure or an abstract creation, aluminum allows artists to push the boundaries of sculptural expression.

Strength in Aluminum

Beauty alone is not enough; strength is equally essential, especially when creating functional or structural pieces. Aluminum’s remarkable strength-to-weight ratio makes it an ideal choice for various applications, from aerospace components to automotive parts. Here’s how strength is integrated into aluminum casting:

- Structural Integrity: Aluminum casting methods ensure that the final product maintains its structural integrity, even in complex and heavy-duty applications.

- Durability: Aluminum’s natural resistance to corrosion makes it suitable for outdoor installations, where it can withstand the test of time and the elements.

- Weight Savings: In industries like automotive and aerospace, the lightweight nature of aluminum reduces fuel consumption and enhances overall efficiency.

Conclusion

Aluminum casting is a testament to human ingenuity, a process that has transformed a common metal into a canvas for artistic expression and a powerhouse for structural and functional applications. The fusion of beauty and strength in aluminum casting showcases the boundless possibilities when science and artistry converge. Whether you’re admiring a meticulously crafted sculpture or benefiting from the strength of an aluminum component, you can appreciate the remarkable journey of this versatile metal from raw material to refined masterpiece.