In the modern electrical and electronics industry, efficiency, precision, and reliability are crucial. One of the key components in electrical distribution systems is the copper busbar. These busbars are used to conduct electricity within switchgear, panel boards, and other electrical apparatus dobladora de barras de cobre. To produce these components efficiently and with consistent quality, manufacturers rely on advanced machinery, known as copper busbar machines.

What is a Copper Busbar Machine?

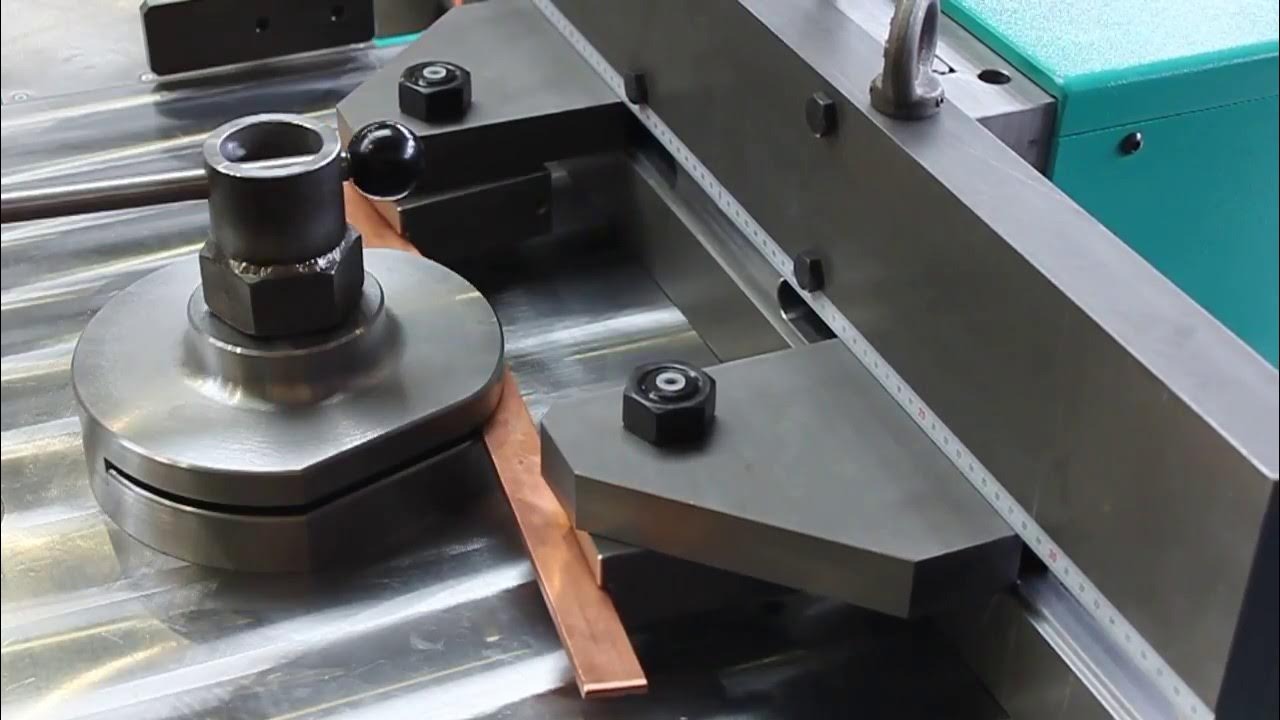

A copper busbar machine is a specialized piece of equipment designed to process copper busbars with precision. Copper busbars are flat, rectangular strips of copper that are essential for conducting large currents safely. The machine automates processes such as:

-

Cutting

-

Punching

-

Bending

-

Shaping

-

Drilling

This automation ensures high productivity, uniform quality, and minimal material wastage.

Key Components of a Copper Busbar Machine

A typical copper busbar machine may include the following components:

-

Hydraulic Cutting Unit: Provides precise and clean cuts for busbars of various thicknesses.

-

Punching Station: Creates holes in busbars for mounting or connecting electrical equipment.

-

Bending Unit: Bends copper busbars at specific angles without damaging the material.

-

Feeding System: Ensures smooth material handling and continuous operation.

-

Control Panel: Usually CNC-based, allowing operators to program dimensions, hole patterns, and bending angles.

Advantages of Using a Copper Busbar Machine

The use of a copper busbar machine offers several benefits to manufacturers:

-

High Precision: CNC or automated controls reduce human error and ensure consistent quality.

-

Time Efficiency: Automated cutting, punching, and bending speeds up production significantly.

-

Reduced Material Wastage: Accurate operations minimize scrap copper.

-

Enhanced Safety: Reduces manual handling of heavy copper bars, lowering the risk of accidents.

-

Cost-Effective Production: Though the initial investment is high, automation reduces labor costs and production time in the long run.

Applications

Copper busbars produced using these machines are widely used in:

-

Electrical panels

-

Switchgear systems

-

Transformers

-

Power distribution units

-

Renewable energy systems like solar inverters and wind turbines

Future Trends

With the increasing demand for electric vehicles, renewable energy, and efficient power distribution, the demand for high-quality copper busbars is growing. Manufacturers are now integrating fully automated CNC busbar machines with smart sensors and IoT capabilities to monitor production and reduce downtime.

Conclusion

The copper busbar machine is a vital tool for modern electrical manufacturing. By combining precision, efficiency, and automation, these machines not only streamline production but also enhance safety and reduce costs. As electrical systems continue to evolve, investing in advanced copper busbar machinery will remain a strategic move for manufacturers aiming to stay competitive in the industry.